Analysis: Rewiring the electric vehicle skills gap

Need to know

- The International Energy Agency predicts there will be 145 million EVs on the roads globally by 2030

- The UK government has committed to phase out sales of new petrol and diesel vehicles by 2030

- To cope with the increased demand for EVs, the UK will need 90,000 EV skilled technicians.

- With only 6.5% of trained technicians for EVs at the moment, there could be a shortfall of 35,700 technicians in 2030

- Bodyshops are hesitant to invest in skills and equipment due to the low volume of EVs on our roads currently.

- Labour rates that have not changed significantly in the last ten years could also be a factor behind the low take-up in training.

- Thatcham urges everyone involved in dealing with EVs should have relevant training and understand the risks associated with handling these vehicles.

- Motor insurers and the repair industry need to collaborate to find the solution.

Repairers must patch up their skills to keep pace with growing demand for electric vehicles but bodyshops say labour rates and current take-up levels are holding them back

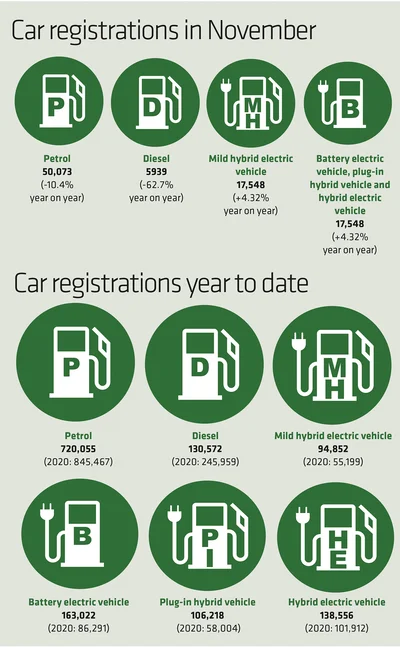

There were 11 million electric vehicles on the world’s roads in 2020 and that number is expected to rise to 145 million by 2030, according to the International Energy Agency,

EV sales are expected to total almost 15 million in 2025 and over 25 million in 2030, representing respectively 10% and later 15% of all road vehicle sales.

One of the commitments made at November’s COP26 summit in Glasgow will see the UK government bring forward the deadline for the ban of new diesel and petrol car sales to 2030.

Motor insurers are increasingly looking to play their part, with the Association of British Insurers encouraging insurers to offer drivers “more sustainable choices” when it comes to repairing and replacement of their vehicles, which could include going electric after a car is written off.

To cope with the increased demand for EVs, the UK will need 90,000 EV skilled technicians, according to the Institute of the Motor Industry. As of 2020, there were just 15,400 qualified technicians in the UK – representing 6.5% of the UK automotive sector – with the IMI predicting a shortfall of 35,700 technicians by 2030.

Steve Nash, CEO of the IMI told Post: “We’ve got a job to do to help all employers, all technicians really understand how quickly this change is going to come.”

Everything the repairers look at – technical skills, knowledge, behaviours around how they repair vehicles - will “really matter in the future”, Nash explained.

With the skills shortage posing a risk to government green plans, the IMI has called on the government to commit funding to support EV skills training. It is suggesting a £15m boost would play a critical role, contributing towards training for up to 75,000 technicians.

Rates

One factor that could be driving low take up of EV training and investment by repairers is disproportionate labour rates. This is the view of Thomas Hudd, national manager at the National Body Repair Association.

In numbers

90,000

EV trained technicians needed by 2030 in the UK

35,700

Predicted shortfall in EV trained technicians by 2030 in the UK

15,400

Number of qualified technicians in 2020 in the UK

11 million

Number of EVs on roads in 2020 globally

145 million

Predicted number of EVs on roads by 2030 globally

2030

UK’s government deadline for the sale of new petrol and diesel cars

Hudd pointed out that labour rates have also not changed significantly over the last 10 years even though repairers have seen huge inbound operating costs inflation.

He said: “For some, either the funding or the business case is not there for investment. People see the rates they pay when they take their car in for a service and assume bodyshops are the same. In reality, as a result of years of procurement intervention, bodyshop rates per hour are often less than a third of what you’d pay to get an Audi serviced, for example.

“There’s very little proactive consideration given for the investment required by repairers to keep up with technology and the chronic skills shortage which is pushing up salary costs within the market.”

Hudd said insurers need to be more aware of the “big issues” at an executive level and collaborate with each other and the repair industry to build a “sustainable future which allows for the training and investment to repair customers’ cars safely in the future”.

He added: “Our fear is a vehicle getting directed to a repairer that is not EV compliant, then a staff member being unwittingly seriously injured or losing life. At that point, everyone would be pointing fingers.”

Gearing up

Some garages are more prepared than others for the shift.

Adam Thurman, director of EV Bodyshops, said: “You usually have two or three hybrid or electric experts in a workshop - if you have 40% EVs in it then you don’t have enough technicians that are dedicated for that.”

All staff at EV Bodyshops are trained to repair EVs. Currently 65% to 70% of cars repaired by the business are electric. This is far from the industry standard, Thurman pointed out.

The repairer boss flagged concerns there could be cases of cars going into bodyshops where technicians do not know how to fix them.

Thurman said: “When I deal with an insurance engineer that goes to lots of garages, we are educating that engineer on the right way to repair that car. If he or she has seen that type of car being repaired before and I’m now telling them we need to do it this way – it makes me think that other places are maybe not doing it. That worries me.”

Everyone involved in the process, from the person that books the repair to the bodyshop technician, should understand EVs according to Adrian Watson, head of engineering research at Thatcham.

EVs can pose different risks to those bodyshops may be used to. They might need to be “quarantined” or “treated with respect” due to battery damage, Watson told Post, and staff should understand what needs to be done in these circumstances.

He said: “Our EV programme is for everyone in a bodyshop not just the guy that’s wielding the spanner and knowing he needs to be insulated. It’s the guy that’s cleaning the car so he knows that he’s making the right choices to be safe and the person moving the vehicle around the bodyshop, perhaps when the battery is removed and the body cell structure is no longer stable. There are so many of these new factors that EVs present and it is about the right knowledge and targeting the right training to the right people.”

Chris Payne, head of networks and engineering at LV, acknowledged insurers have responsibility to ensure repair networks are EV trained.

He said: “If we don’t continue to make sure staff are trained as the training evolves and new training comes in, there won’t be enough staff because the growth of EVs over the next five to ten years is going to be quite exponential and we need to keep up with the demand of what that looks like when cars need repairing because increasingly manufacturers are bringing newer models into the industry.”

Claims growth

EVs are making up an increasing proportion of insurance claims. However according to Allianz motor damage strategy manager Nick Rossiter while the EV repairs volumes are increasing, garages do not want to make the investment in training, space or the equipment as the investment is “too big” and it is “too early”.

He said: “Particularly garages that operate multi-sites - they can have specialist sites where their technicians are trained on repairing the vehicles, but primarily it’s about knowing how to power them down and remove any danger to the operatives who are repairing that vehicle - most repairers will not have the ability to actually repair batteries if they’re damaged.

“That’s a future focus area, but it’s more about being able to repair the bodywork at the vehicle safely while there is a high voltage battery connected to the vehicle.”

He said that currently Allianz does not have a problem finding capable repairers and predicts that as the volumes increase, the investment in training will also increase.

He said: “In five or ten years, it will be the normal vehicle coming through the doors. It is a transition that they need to make.

“But certainly [there are] conversations about the rates that we pay to garages and the discounts that we might expect during Covid and for our approved repair network our focus has been much more about having a sustainable relationship that allows those repairers to make the investments that they need to make in the future vehicle technology.

“We need to support our repairers to make those investments in the training in the skills.”

Sharing

To support its supply chain, another insurer is facilitating a space for repairers to share information and knowledge.

Ageas claims director Robin Challand explained: “Our repair network can facilitate any EV repair. Where a repair is particularly specialist, our centres have the ability to refer to another or send the vehicle to a specialist centre. We also have a dedicated online community, where our repair centres can share best practice and advice as recently happened when one of our repair centres was looking for information on a Tesla process.”

To create the correct infrastructure to deal with the growing demand for EVs insurance industry and repair industry will “undoubtedly need to come together” according to Robert McWilliams, approved repairer vendor manager for Zurich.

“Industry bodies such as Thatcham, as well as the NBRA and the Institute for Automotive Assessors and Engineers, are continually highlighting the changing nature of repairs on modern day vehicles and the investment required at bodyshop level to carry out these repairs.”

But McWilliams was upbeat.

“With continued dialogue, I am confident we will find a solution to the challenges we are currently faced with,” he concluded.

Only users who have a paid subscription or are part of a corporate subscription are able to print or copy content.

To access these options, along with all other subscription benefits, please contact info@postonline.co.uk or view our subscription options here: https://subscriptions.postonline.co.uk/subscribe

You are currently unable to print this content. Please contact info@postonline.co.uk to find out more.

You are currently unable to copy this content. Please contact info@postonline.co.uk to find out more.

Copyright Infopro Digital Limited. All rights reserved.

As outlined in our terms and conditions, https://www.infopro-digital.com/terms-and-conditions/subscriptions/ (point 2.4), printing is limited to a single copy.

If you would like to purchase additional rights please email info@postonline.co.uk

Copyright Infopro Digital Limited. All rights reserved.

You may share this content using our article tools. As outlined in our terms and conditions, https://www.infopro-digital.com/terms-and-conditions/subscriptions/ (clause 2.4), an Authorised User may only make one copy of the materials for their own personal use. You must also comply with the restrictions in clause 2.5.

If you would like to purchase additional rights please email info@postonline.co.uk